Like any wood project that comes off of a CNC router, the Asana bot needs a lot of clean up and finishing work to shine. The majority of this is sanding and oiling before finishing with wax (or another top coat).

My current process is:

Take job off 4-axis mill and cut parts from larger block

Sand off tabs

Sand the parts from 220 -> 400

Inlay brass powder on body with CA glue

Sand body + brass to even 400

Oil parts with tung oil

Repeat #4 every 24 hours until I like the color

Sand from 400 -> 600

3 step wax on lathe buffing wheel

So much sanding. So much tung oil. Starting at 220, going up to 600 prior to waxing.

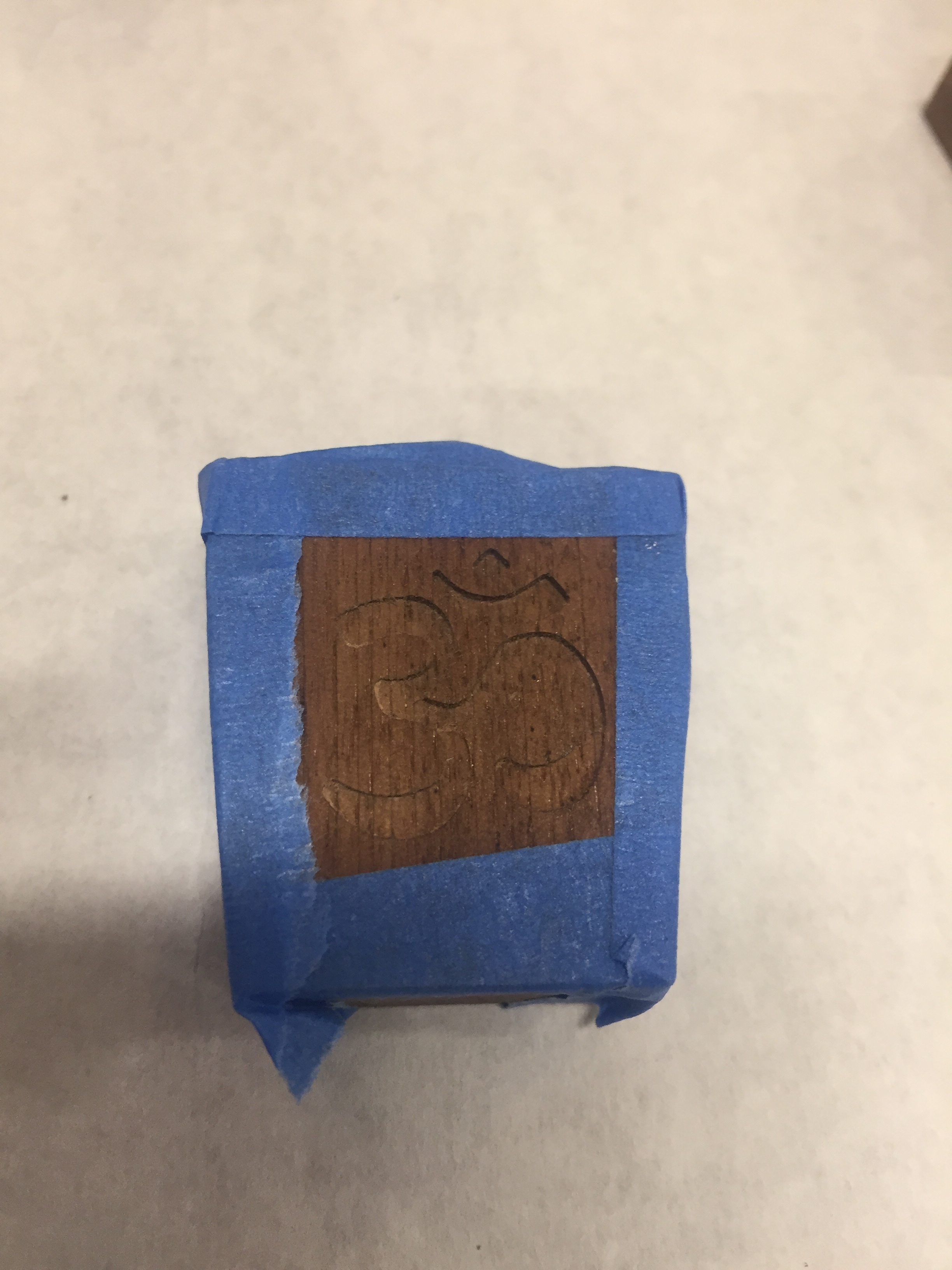

Test fitting arms and heads while sanding/oiling

So far, the biggest challenge has been getting the brass ohm inlay right. I’m using brass powder and cyanoacrylate (CA) glue rather than attempting to inlay a solid piece of brass. My current process is: clean up the inlay area with high grit sandpaper (400+), put multiple clear coats on top, add brass powder, add CA glue, sand. Ultimately, getting a great result seems to come down to getting 3 variables correct: cut depth for the inlay, amount of clear coat before attempting inlay, and amount of inlay powder used.

Using Krylon matte finish for the clearcoat

For me, 2 thin coats of clear coat has been a good place start. I’m still having issues with the powder getting deep into the open grains of the walnut, but it’s significantly better than early attempts with 1 coat. 1/16”, cut with a 1/32” bit, has proven to be a good depth for the inlay cut.

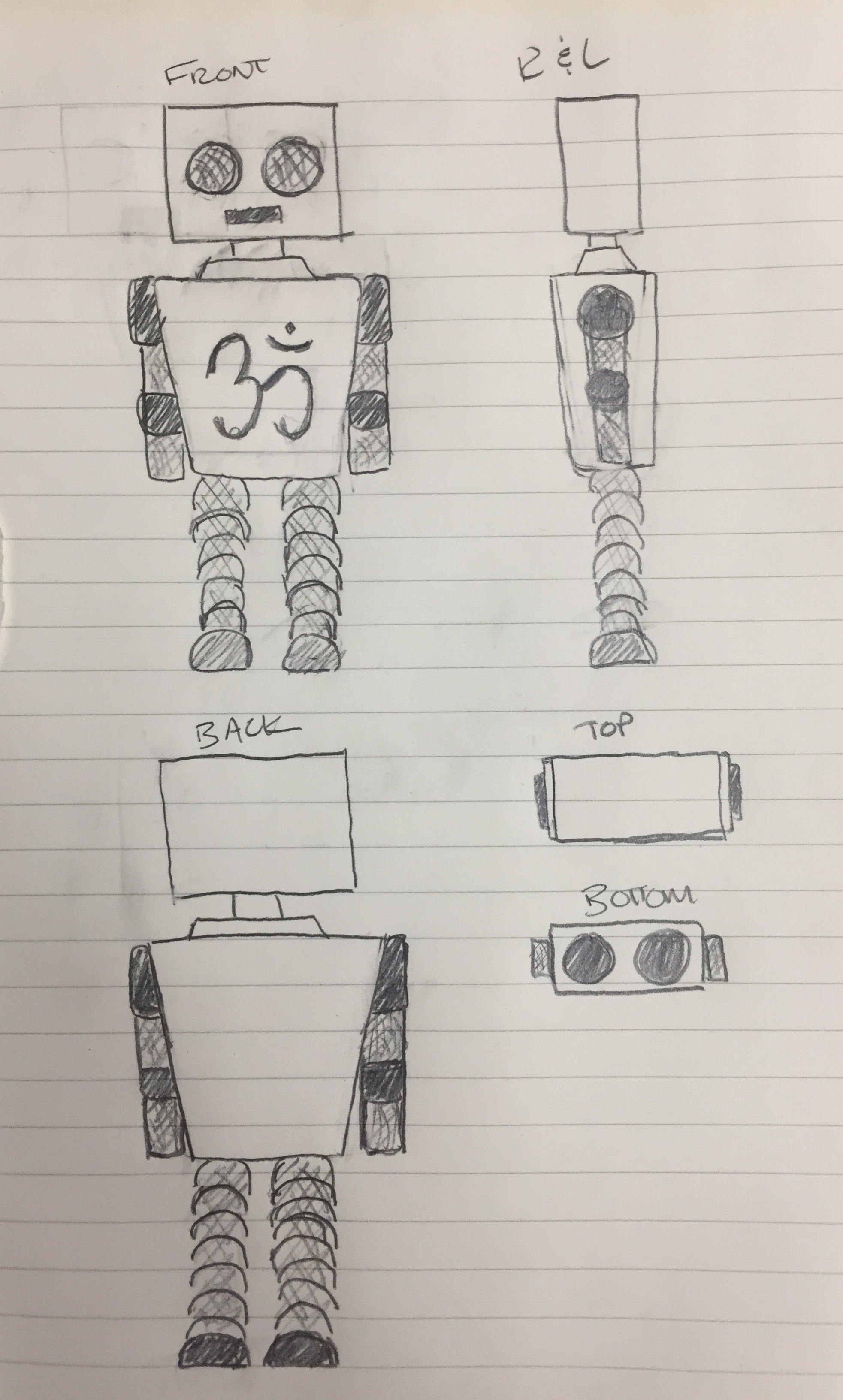

Continuing work on my original character for Art Toy Design, current named Yoga Bot 9000. Bringing him into 3D was a fun and interesting challenge--how does a robot with no elbow/knee joints do yoga?

Continuing work on my original character for Art Toy Design, current named Yoga Bot 9000. Bringing him into 3D was a fun and interesting challenge--how does a robot with no elbow/knee joints do yoga?